Premium Custom Men's Black Tracksuits | Embroidered Sportswear Manufacturing

- Model

- MY-232

Item specifics

- Color

- custom colors

- Delivery time for bulk order

- 10-30 days after confirming pre-production samples

- FOB port

- Shenzhen or Guangzhou

Review

Description

Item | custom black tracksuit mens with embroidery | ||

Features | Customize your logo with patch embroidery on tracksuits | ||

|

Fabric

|

Customize the fabric you like ,cotton or polyester,french terry or fleece etc.

|

||

|

Colors

|

Customize the color you like,we provide color swatch/color book for option.

|

||

|

Sizes

|

Customize the size you like,if you don’t have size chart,we can provide size chart for your reference. |

||

Plate making time | 7-15 days | ||

MOQ | 50-100 pieces per color per design | ||

Shipping time | 4-7 days by express like DHL,UPS, FEDEX, TNT. It will spend at least one month by sea to North America and Europe. | ||

Tags&labels&zippers&buttons | we advise to customize the tags,labels, zippers, buttons after you decide to place the bulk order from us, it can help you save time and cost . | ||

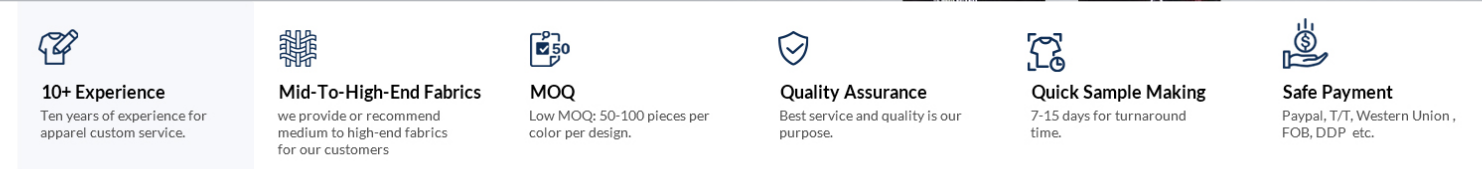

Step 1: Selecting the Right Supplier

Choosing a reliable manufacturer is the foundation of a successful project. Start by conducting thorough research to identify suppliers who specialize in activewear and offer customization services. Evaluate their experience, portfolio, and client reviews. Confirm their ability to handle your preferred customization techniques, such as embroidery, printing, or technical stitching. Additionally, discuss practical details like **Minimum Order Quantity (MOQ)**, pricing structure, production lead times, and quality control measures. A trustworthy supplier will be transparent and responsive, providing clear answers to all your questions.

Step 2: Sending Your Design Tech Pack

Once you have selected a supplier, the next step is to share a detailed **Technical Package (Tech Pack)**. This document is crucial for accurate communication and should include:

- **Technical sketches** of the front, back, and side views of the tracksuit.

- **Measurement charts** with precise garment dimensions.

- **Color references** (e.g., Pantone codes) for each part of the design.

- **Logo/embroidery artwork** in vector format (e.g., AI, EPS) with clear placement instructions.

- **Labeling and packaging requirements**.

A complete tech pack helps the manufacturer understand your expectations clearly and minimizes errors during production.

Step 3: Choosing Fabrics and Confirming Details

Material selection directly affects the comfort, functionality, and look of your tracksuit. Work with your supplier to choose suitable fabrics based on your needs:

- **Performance-focused**: Moisture-wicking polyester or nylon blends.

- **Comfort-focused**: Soft cotton blends, French terry, or lightweight fleece.

- **Elastic components**: Ribbed cuffs, waistbands, and collars for fit and flexibility.

Discuss and confirm all **construction details**, such as zipper types, pocket styles, seam finishes, and any special features like reflective elements or ventilation panels. Request physical **fabric swatches** to verify color, texture, weight, and stretch before finalizing.

Step 4: Sampling and Review

Before proceeding with full production, it is essential to create a **prototype sample**. Provide the manufacturer with all approved materials and the finalized tech pack to produce a sample according to your specifications. Once received, carefully evaluate the sample for:

- **Fit and comfort** (consider having someone of the intended size try it on).

- **Design accuracy**, including color, print/embroidery quality, and placement.

- **Construction quality**, such as stitching durability and finishing.

Share detailed feedback with the supplier and request revisions if necessary. Only approve the sample once you are fully satisfied, as it will serve as the reference for mass production.