custom stacked pants men with puff printing factory | wholesale clothing manufacturer in china

- Model

- MY-222

Item specifics

- Color

- custom colors

- Delivery time for bulk order

- 10-30 days after confirming pre-production samples

- FOB port

- Shenzhen or Guangzhou

Review

Description

Item | custom stacked pants men with puff printing factory | ||

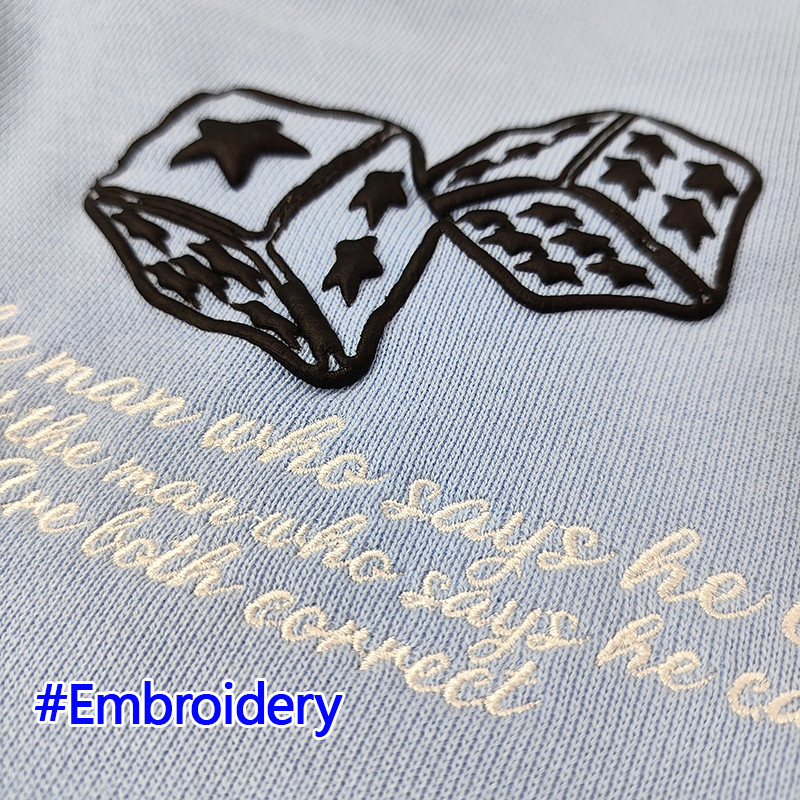

Features | Customize your logo with puff printing on sweatpants | ||

|

Fabric

|

Customize the fabric you like ,cotton or polyester,french terry or fleece etc.

|

||

|

Colors

|

Customize the color you like,we provide color swatch/color book for option.

|

||

|

Sizes

|

Customize the size you like,if you don’t have size chart,we can provide size chart for your reference. |

||

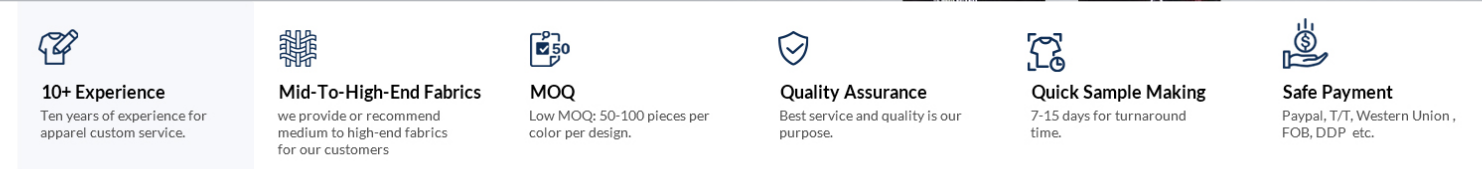

Plate making time | 7-15 days | ||

MOQ | 50-100 pieces per color per design | ||

Shipping time | 4-7 days by express like DHL,UPS, FEDEX, TNT. It will spend at least one month by sea to North America and Europe. | ||

Tags&labels&zippers&buttons | we advise to customize the tags,labels, zippers, buttons after you decide to place the bulk order from us, it can help you save time and cost. | ||

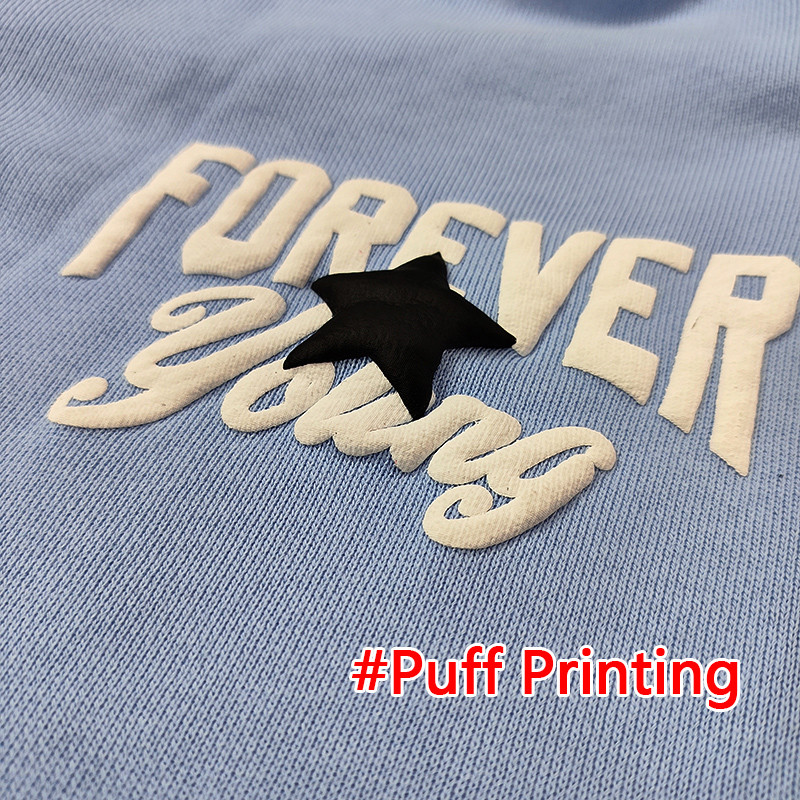

puff printing process on custom stacked pants men, referred to as foaming/puff printing.

It is to add several chemical substances with a certain proportion of high expansion coefficient in the glue printing dye, and the printing position is blistered at a high temperature of 200-300 degrees after drying, to achieve a three-dimensional effect similar to "relief".

Foaming/puff printing is also known as three-dimensional printing. Foaming printing process is developed on the basis of glue printing process. Foaming printing process can do high, medium and low foaming effect according to the requirements of substrate. The advantages are strong three-dimensional sense, printing surface prominent, expansion. It is widely used in cotton cloth, nylon cloth and other materials.

The raw material of puff printing is made of thermoplastic hencoop, blowing agent, coloring agent, etc.

Taking clothing foam printing and socks foam printing as examples, the principle of foam technology used is physical foam. When the microcapsule resin mixed with printing pulp meets heat, the resin solvent forms gas, and then becomes bubbles, and the volume increases accordingly, which is the principle of foaming printing that we usually come into contact with.