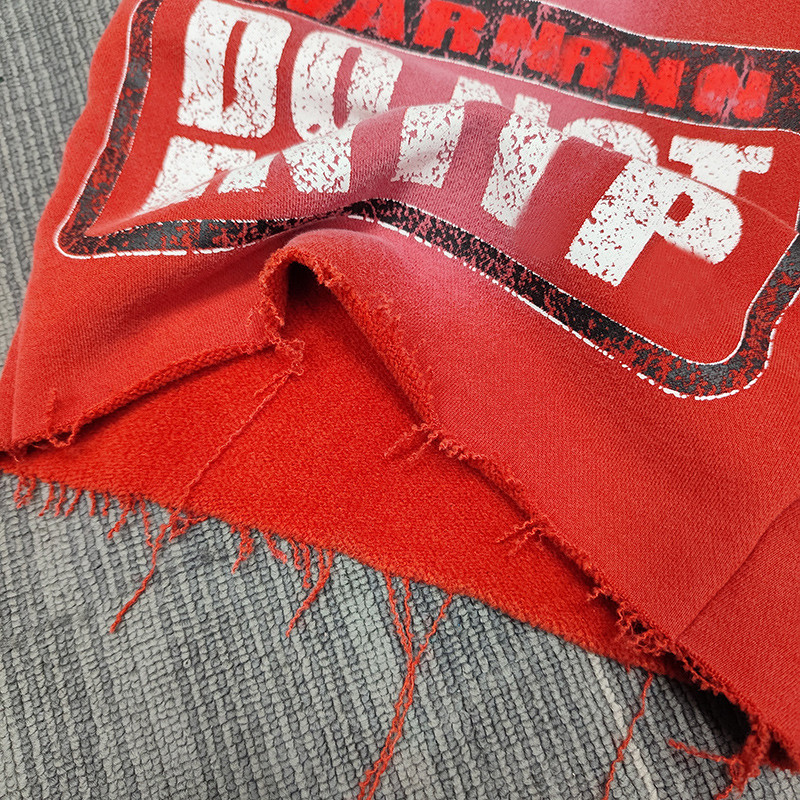

wholesale mens faded shorts with screen printing | hip hop clothing manufacturers

- Model

- MY-213

Item specifics

- Color

- custom colors

- Delivery time for bulk order

- 10-30 days after confirming pre-production samples

- FOB port

- Shenzhen or Guangzhou

Review

Description

Item | wholesale mens faded shorts with screen printing vendor | ||

Features | Customize your logo with screen printing on shorts | ||

|

Fabric

|

Customize the fabric you like ,cotton or polyester,french terry or fleece etc.

|

||

|

Colors

|

Customize the color you like,we provide color swatch/color book for option.

|

||

|

Sizes

|

Customize the size you like,if you don’t have size chart,we can provide size chart for your reference. |

||

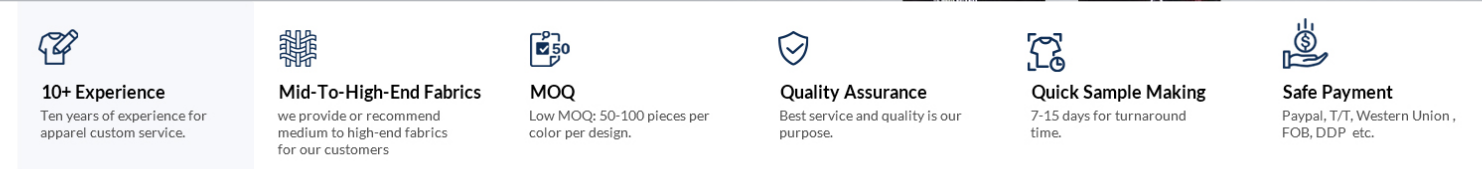

Plate making time | 7-15 days | ||

MOQ | 50-100 pieces per color per design | ||

Shipping time | 4-7 days by express like DHL,UPS, FEDEX, TNT. It will spend at least one month by sea to North America and Europe. | ||

Tags&labels&zippers&buttons | we advise to customize the tags,labels, zippers, buttons after you decide to placethe bulk order from us, it can help you save time and cost. | ||

Offset/screen printing is usually done by using a special press to print ink onto the mens faded shorts. This process can be used to print a variety of patterns and designs, including logos, text, images, etc. The process involves preparing the surface of the mens faded shorts, applying plate ink, and then pressing the plate onto the shorts. In this way, after a single printing on the press, you can get a complete print of the mens faded shorts.

When applying offset/screen printing process on the mens faded shorts , the following points need to be paid attention to:

1. The surface of the shorts must be dry, smooth and even. If the surface is uneven or there are stains, there will be printing is not clear or pattern problems.

2. The choice of ink is very important, because different ink is suitable for different materials and printing presses. If you choose the wrong ink, it may lead to print fading, shedding and other problems.

3. Before printing, sample testing is needed to ensure that the quality and effect of printed matter meet the requirements.

4. In the printing process, it is necessary to control the pressure and speed of the printing plate, otherwise the quality of the printing matter will be affected.

5. Finally, the printing material needs to be dried to ensure that it is durable and will not fade or fall off during wearing or cleaning.